Background Technology of prescription dispensing machine

Date: 2024-06-06 Categories: Industry News Hits: 361

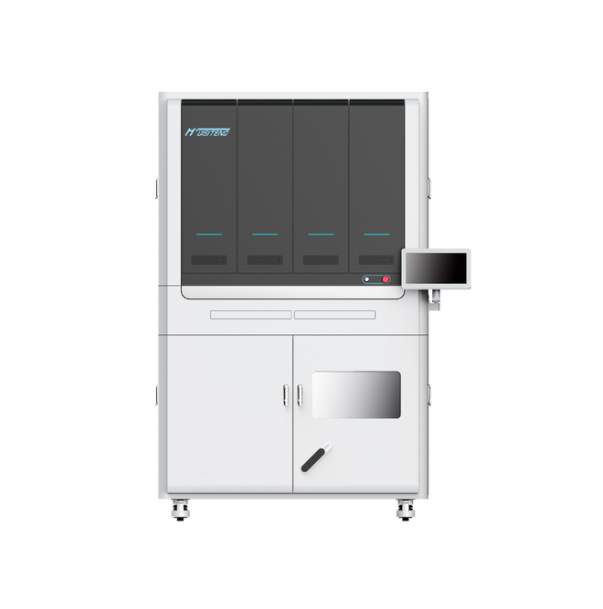

With the rapid development of the medical and pharmaceutical industry, traditional manual dispensing methods are difficult to adapt to the improvement of hospital pharmacy management level and the requirements for pharmacy work in the new century. The new dispensing model fully reflects the overall strength of the hospital, ensuring more accurate and accurate dispensing, providing more comprehensive and high-quality services for clinical departments, improving service quality and work efficiency, and providing reliable data basis for high-level management of pharmacies. The Fully Automated Drug Subcontracting System (ATDPS) is an innovative pharmacy solution designed to achieve safe and stable automation through new hospital and pharmacy management, as well as efficient and accurate data processing processes. From selecting the correct medication to storing, counting, filling, and packaging medication, ATDPS can fully automate all the dispensing processes. After inputting the medication instructions (mo) provided by the hospital or pharmacy into the system, relevant information and medication instructions can be printed based on the patient's mo, in order to better serve the patient.

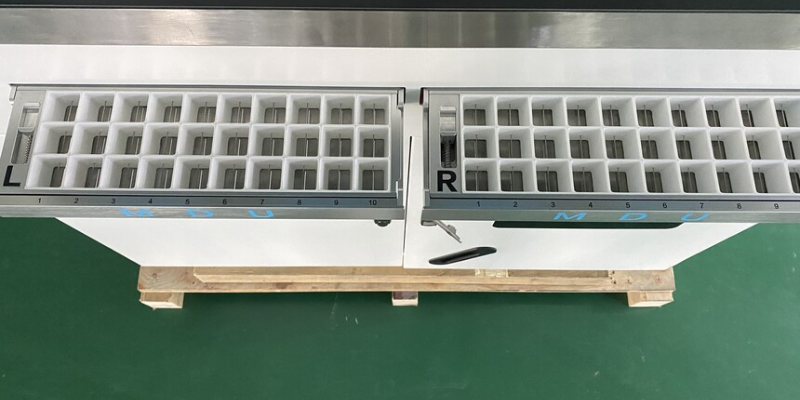

However, for some uncommon drugs, special shaped drugs, and drugs added by pharmacists on a temporary basis, if you want to add them to the working drug dispensing machine, you need to manually dispense drugs on an external tray for dosing. Currently, the temporary drug boxes used to receive drugs from the external tray are single row moving disks, fixed to the conveyor belt by multiple small boxes, and the external tray delivers one row of drugs at a time, When the conveyor belt drives the mobile box to rotate to the edge of the conveyor belt, the drugs are put into the packaging system below. After the drugs in the mobile disk are fed, the conveyor belt drives the mobile disk to reset to receive the next row of drugs in the outer swing disk. Due to the multiple rows of drugs in the outer swing disk, the outer swing disk needs to wait for the mobile disk to receive all the drugs before exiting to receive new drugs, which takes a long time and is very inefficient.

Huisiteng robotic prescriptio...

Huisiteng robotic prescriptio...  High Speed Automatic Dispensar...

High Speed Automatic Dispensar...  IPHA-BA1 Automatic Medicine St...

IPHA-BA1 Automatic Medicine St...  Packing bag

Packing bag  Medicine dispensing cells

Medicine dispensing cells